Brewing

Great Beers!!!

|

|

Beer is proof that God

loves us and wants us to be happy- Benjamin Franklin

After more than 4 years in Germany, coming back to the United States was a

big shock. I'm just not a crappy, tasteless beer fan. My very close friend,

former neighbor, and professional brewer, David Huls, is 80% responsible for

me diving into brewing; the other 20% is due to loving good beers. We started

brewing together in 1998 and Big Dave got so into it that he got his brewing certificate from

UC-Davis and went pro. He's now a Master Brewer for Gordon Biersch.

Big Dave is a Silver Medal winner in the Great American Brew Fest for his

Strong Scotch Ale!!! If you

are considering brewing, finding a good friend and beer mentor like Dave is

important as well as finding the local brew stores. Up in Dallas?, Kelly and

his team at Homebrew Headquarters has

been very helpful for bouncing things off of, getting equipment, and fresh

hops. Living in Austin, I have found that Austin Homebrew is a great home brew

shop with an extremely helpful staff. Joining a home-brew club is a good idea

as you'll learn a lot from more experienced brewers and may even have the

opportunity of helping out newbies. I am currently

a member of the Austin Zealots

homebrew club. My

brewing is all-grain, which means I mix several types malted barley depending

on the malt profile and taste I want to achieve, and ("mash") the

grain with a malt mill I

separate the liquid from the spent grain, boil and add the finest hops money

can buy. The boiling liquid (“called wort at this

point”) is then cooled and transferred to fermenters. I then float wonderful little yeasts in the

wort, to produce the best beers known to this

corner of Austin. I can say that because now that Big Dave has gone pro, he

doesn't home brew as much...just teasing Dave...anyway, the yeast consume the

sugar produced during the mashing process and convert that sugar to alcohol

and CO2. Let's

take a look at some of the steps and the equipment. The first step is to

decide what style of beer that you want to produce, or if the beer you are

designing will hit any pre-defined style. There are two main categories of

beer commonly recognized: ales and lagers. Ales are fermented with yeast that

favor warm temperatures around 65-75 °F and Lagers are fermented with yeast

that favor colder temperatures around 48-54 °F. Ales ferment faster and have

fruitier notes due to the esters and fusels produced by yeast during the

relatively fast fermentation, about 2 weeks, whereas lagers tend to be

cleaner in taste and ferment much slower, taking a month or more to ferment. Whether

an Ale or a Lager decision, when designing the next great beer, you also need

to take into account season, maltiness, dryness,

darkness, lightness, bitterness, aroma, head retention, etc...but is hopefully up to your tastes. I love all sorts of

different brews and, fortunately enough, have the use of our chest freezer to

control fermentation temps. That simply means that I can ferment at higher

temps for an Ale or lower temps for a Lager. Here is

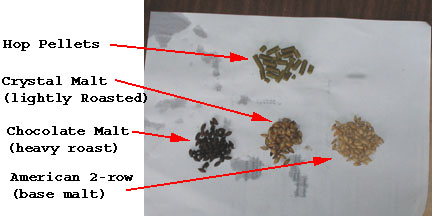

an example of some of the ingredients: Ingredients

For the

most part, a base malt (2-row, pilsner, vienna) makes up the largest portion of malt you will

use. As an example, for an IPA, I'll use 22 lbs of American 2-row as the base

malt. There are many malts that can be used it impart flavor and color to a

beer. 2 are shown above, 40 Lovobond Crystal Malt

and Chocolate Malt. Brewers use the variety of base and specialty malts to acheive the malt character, color, and head retention

characteristics when designing a great beer. Hops are

used in the boil to add bitterness, flavor and aroma to your beer, balancing

the maltiness and providing a clean finish to your

beer. Once you

have decided on what you want to brew, then it's time for recipe formulation.

I use a program called ProMash

to help with calculations and adjustments during the recipe formulation and

brewing process. I've included my favorite recipes (see favorite recipe

links). Milling Grain with Malt

Mill and Trusty Dewalt

Milled Grain with Malt

Mill

Mash Tun Once the

grain is milled, you heat water to an appropriate temp (range of 146 °F to

162 °F, depending on beer style) to activate enzymes; alpha and beta amylase,

which break down starches into sugars. Basically, we are making yeast food.

Yeast break down the sugars into alcohol and CO2. Without getting too geeky,

brewers use temperature to tune the malt profile within the above range;

148-152 °F yields a more fermentable wort and drier

beer (think pale ales and pilsners) whereas 155-160 °F yield a less

fermentable wort delivering more complex, maltier beer (think bocks and brown ales). So

temperature control is critical, If the temp is too cold, the enzymes will

not activate, and if the temp is too hot, you will denature the enzymes and

won't be able to recover the process. The ProMash

software helps me make these critical temperature calculations. I try to hit

a "strike" temp that is about 20°F to 25°F hotter than the target

temp in that I know I will loose some temp due to

pumping water into a cold keg and introducing cold grain into the hot water.

The ProMash software helps me do these

calculations. Once the appropriate amount of hot water is pumped across into

the mash tun, I mix in the milled grain. Note that

the mash tun has a false bottom. The grain settles

on the false bottom and acts as a natural filter. Water is heated in the hot

liquor tank tank to the right in the picture below,

and then transfered to the mash tun

(keg in the middle). Brew Rack The

figure above gives an overall view of my brew rack and brewing equipment. My

system comfortably produces 10 gallon batches. My mash/lauter

tun is in the middle, with the sparge

tun high to the left for gravity-based flow in sparging. I heat water in the hot liquor tank, to the

right. The Mash in the Center

Tank

Once the

grain has steeped in the water for about an hour, really whatever time it

takes for the starch to sugar conversion and color extraction, it is time for

("mashing out"). In the mash-out process, the grain is rinsed with

hot water, usually around 172°F , in a process

called sparging. At the same time, the liquid is

very slowly pumped into the hot liquor tank for boiling. Slow, deliberate

run-off from the lauter tun

to the hot liquor tank is one of the most important steps, and helps to

ensure the best extraction of sugars from the grain bed. Once in the hot

liquor tank, the extraction is called Wort. Mashing Out There I

am mashing-out. Note the sparge arm from the sparge tank goes into the top of the lauter

tun, and out of the bottom of the lauter tun, I am adjusting the

flow of the runnoff into the hot liquor tank. This

process is aided by the food grade pump. I'll let about 10 gallons of wort come across, stop the process and use a hydrometer

to check the amount of sugar in solution. The amount of sugar in solution is

important in that it shows how efficient the mashing process was and also is

a good indicator of what alcohol content the beer will eventually have. If I

have done everything correctly, and the run-off was controlled, I can go

ahead and continue the run-off to 12 1/2 gallons for the boil. At that point,

I will use a hydrometer to check the wort again. I

can expect that I am going to loose 2 gallons of wort to evaporation during the boil. Boiling

is done to sterilize the wort. As mentioned

earlier, Hops are added during the boil to provide bittering,

hop flavor, and aroma. Boiling (right-side

tank)

Whatever

you do, USE FRESH HOPS!!! Bittering additions are

done fairly early in the boil to extract and break down certain resins in the

hops, flavoring in the middle, whereas aroma hop additions are added late or

at the end of the boil. There are as many variety of

hops to use as there are malts. The type you use should be typical of the

style of beer you are brewing, however,

experimentation is the fun part of being a home brewer. Racking Off into Fermentation

Vessels The hot wort flows through a Counter-Flow Chiller. This is a

contraption that I built based on instructions found on the internet with

help from Dave. We wind 20' of 1/4" flexible copper tube through a standand garden hose. The hot wort

flows through the copper tube while at the same time, cold water flows around

the copper allowing heat to be transferred to the cold water. When the wort hits the fermentation vessel, it's

temperature is about 1 or 2 degrees above the water temperature. The reason

for a chiller is to bring the wort temperature down

to a temperature that won't kill the yeast that are about to be pitched into

the fermentation vessels. Without a chiller, you would have to wait several

hours to a day for the wort to adjust to a

non-lethal, usable temperature. As can be

seen above, I use a chest freezer as a fermenter. My

wife is none-to-happy about this, but a chest

freezer with a temperature controller is a great fermenter

because it is so well insulated. I can ferment ales at 65 °F to 68 °F,

ferment lagers at 48 °F to 55 °F, crash beers to freezing, and can force

carbonate at 32 degrees. All due to a chest freezer and Johnson temperature

control unit. Yeast consume sugars and produce two things; CO2 and alcohol. A

brewer can choose to vent the CO2 as I do with the blow-off hoses and the

bucket of bleach water, or naturally carbonate by not venting the

fermentation vessels. I choose to vent the CO2 for a variety of reasons: Nope, I

don't bottle (that's a pain in the bass-ale...). For most light colored beers,

I will use a brew-plate filter from Williams Brewing (see link) to clarify

and polish my beers. For darker beers, it really isn't necessary and I just

rack the fermented beer off to another Corny keg for serving. I push the beer

with 20 lb. CO2. Beer Friends (adults -

you think I'm that crazy...) - Waiting for a free sample

Favorite Recipes Okay, so

I'm an Italian brewer that likes to name beers, but this American Style Pale

Ale Hop Monster packs one heck of a hops punch. For special fun, try

dry-hopping this powerful beer with either Amarillo or Cascade hops. Use a

single-step, infusion mash and hit a strike temp of 152 °F and you'll be on

the money for a clean-tasting beer meant for your favorite hop-head. Note the

use of a small amount of Carapils Dextrin Malt. I

use 1/2 pound for body, mouthfeel and head

retention. I have to tell you, this is one of my wife's favorite beers.

It never

fails that when I am brewing this beer, no matter the season, a few bees come

out to take a wiff of the boil. I grab my trusty

brewing spoon and bat the little bastards into the boiling wort (I better watch out for those crazed PETA

whacko's...). Thus the name for this wonderful American-style brown ale. You

want to accentuate the malt character on this beer, so your strike temp

should be about 156 °F degrees.

Petden, in Satellite Beach Florida, is where I cut my surfing teeth. Petden was the hotest spot in

town for surf and for some strange reason (fantasizing about my mis-spent youth maybe...) I think of Petden

when I drink this brew. Petden Porter shows off a roasty chocolate and nutty

90-Lovibond Crystal malt, which is just rippin hot.

A-Framers and Mark Reality beach folks were bud drinking gremmies. This

Porter is much like a day at Petden; the first beer

is a smooth paddle out on a fall to winter day and what follows are toasty

waves to the end. An interesting twist to this beer is to pour in a pot of

coffee or steep coffee grounds in the secondary (Chris Colby - thanks for the

tip) to create a Coffee-Porter. You want to accentuate the malt character on

this beer, so your strike temp should be about 156 °F degrees.

I said

Dude...he said, Dude...we said Dude!!! This is just a fun, easy going, summer

beer. The fun part is mixing a decidely German malt

bill with hops similar to an American Pale Ale...and San Francisco Lager

yeast...what a mix...A little bit of something for everyone, beach sitter,

long-boarder, short-boarder, republican, democrat, or middle of the fencer..except I don't think a dem would

never brew... they'd just come by and consume... Anyway, whatever your board

or politics, use a single-step infusion mash with a target of 152°F

This beer

is brewed in honor of my Son-in-law, Bobby Skeen and also Stevey-Ray

Vaughn. It's a long story, but suffice it to say,

the first time we met Bobby, he locked horns with the Dubbel

and the Dubbel won!!! This Belgian is a strong

beer, with a bubble-gum nose that really warms a cold Dallas January. Okay,

so it's not that cold in Dallas, so what, drink up!!!

Mai-oh Maibock AKA Catalano Crippler I have to

tell you, this is one of my favorite beers. I try to brew this in early

January and wait till May before tapping this hefty brew...never made it past

Feb 15. Maibock should be a strong and malty beer

with an amber tone and balanced noble hops. As you can tell from the recipe,

my interpretation has an uncharacteristically high IBU - more hops than the

style calls for. Well, that's the fun of homebrewing.

I like hops!!! This beer packs a bit of alcohol, with an OG of 1.072 and a

usual FG of 1.016. Careful now...

Audrey

(my wife) and I spent 4 1/2 years in Germany serving our country. What an

absolute kick in the pants that was. We just had a ball, and the German

pilsner beers were one of the reasons. Bitte ein Bit (please give me a Bitburger

Pils) was one of our favorites. Audrey also loves

pigs, so there you have it. Again note a high IBU...well, she LOVES hops,

too. This is

the only beer that I use a two-step mash process. For ales and most lagers,

this is a total waste of time. However, a pilsner needs to be super clean, so

I bring it to 145°F for 30 minutes with a thick mash for the beta-amylase

rest, and then pump more hot water in to bring the mash to 158°F for the

alpha-amylase rest. If you've got the equipment and can do it, okay,

otherwise hit a strike temp of 152°F and you'll be okay. Well, the lady wants

a pils, I better get brewing!!!

This beer

is named after the first peak break at Sebastian Inlet on the east coast of

sunny Florida. Did I tell you I surf... Anyway,

First Peak, like this beer, starts fast and big. It's a big malty bottom turn

with a clean roasty-toasty off the lip, that delivers all the way through, then a cut-back

for another. Totally tubular!!! This beer

boasts an alcohol by volume around 8%, which makes it a classic winter

warmer. Strong Scotch Ale's, aka Wee Heavy's, are known for having a hint of

smoky flavor delivered mostly through the yeast. I also use a Scottish Peated Malt, but only a very small amount as it is easy

to overdue and will overwhelm your beer. A First Peak, thinking about good

surf to come and a Green Bay game...well, it doesn't get much better...Give

Favre some blocking, dammit!!!

Festbier is another favorite...alright, you've guessed that they are all

favorites...I love beer, and so do you if you've read this far. This

wonderful meal in a glass is brewed to the Santiago Graf interpretation of

strong Vienna style festival beers. Think Negro-Modello.

Simply put, I throw a handful of chocolate malt in. This is a great fall brew

warmer that puts a crooked smile on the Halloween pumpkin.

Winter

Steamer is my attempt at going after Anchor's 1996 Christmas Ale...oh what a

beer that was. I think that you'll find this to be pretty close. With an 8%

alcohol by volume, this brew will cure the flew, colds and warm you to the core. Winter

Steamer is a spice beer, which shows off orange zest, cinnamon, ginger, correander, nutmeg and a hint of clove. The orange

zest/rinds (whatever) go in a steeping bag at 10

minutes into a 70 minute boil. My experience has shown that it takes a long

time for the orange oil flavor to assimilate into the boil. I add the spices

with 5 minutes left so that the spices provide aroma without overwhelming the

flavoring of the beer. Initially, this brew tastes like pumpkin pie in a

glass, but within a month mellows enjoyably. As with most high alcohol

content beers, especially spice beers, a couple of months of aging are

required.

Two

glasses of this hefty brew will have you singing that grand old Christmas

tune just as bad and as loud as me (believe me, I am a much better brewer

than singer). My wife gets a big kick out of this every year by hosting a

Christmas Holiday party and having me lead in singing Christmas carols. I'll

put it this way, my good friends come for the beer, not the singing... This beer

is modeled after Chimay Grande Reserve and boasts a

9 or so percent alcohol by volume. You may already be onto me here, Maibock, Festbier, Winter

Steamer, and then this wonder in a glass, seems a trend toward higher alcohol

content brews...you'd think I lived in freakin'

Minnesota. Okay, one of the joys of home brewing is being able to target a

certain seasonal or specialty brew and then going after it. Due to the amount

of grain required for this beer, I just brew a 5 gallon batch (it's hard to

fit 43 lbs of grain into a 15 gal keg 1/2 full of hot water)...

Have a Berry, Berry

Christmas Ale This is

my Christmas Ale for 2004 and 2006. Originally brewed it turned out better

than I could have imagined, so this year I threw in 2 lbs more frozen rasberries in. I will definitely brew this again as it is

crisp, full of alcohol for sipping during frigid Austin Texas winters. The

wife likes it, Big Dave has given it his blessings,

and neighbors from all around have become new friends after quaffing this

puppy. The base

for this fruit beer is an Imperial Pale ale. I threw

in about 8 lbs of frozen rasberries directly into

the fermenters for a 10 gallon total batch. To

ensure that the rasberries would not infect the

beer, I steamed them for roughly 5 minutes; not long enough to loose any flavor, but long enough to hopefully rupture

cell walls of wild yeast or bacteria. Then I pitched fresh yeast (White labs

051) on top and let 'er rip. Note to self: the rasberries contain fermentable sugars (fructose), which

will add to the original gravity. Man, there is some alcohol in this

flavorful brew!!! From a

recipe formulation perspective, I made the assumption that sugar represents 8

percent of the weight of the rasberries. So when

you see rasberries and only about 1 lb of sugar,

understand that represents 8-10 lbs of rasberries.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||